表的内容

叶片夹具机械工程的设计与制作188金宝搏怎么样

摘要

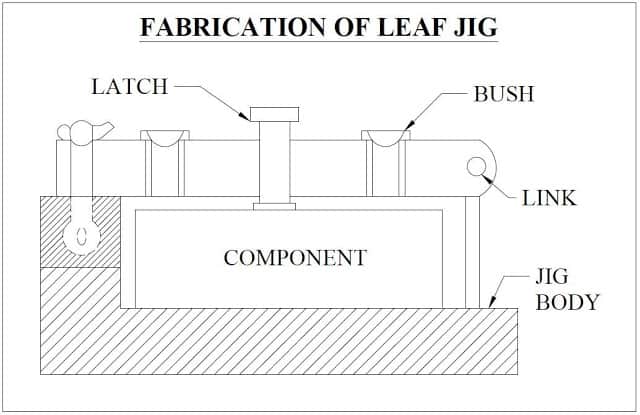

这个项目是基于工作保持装置的需要。这种设计和制造将使钻孔、铰孔、攻丝等操作更容易,即使工作轮廓是Angular的。我们的项目主要是由设计和制造“叶夹具”它涵盖了对工件指定尺寸的绝对设计。角型夹具允许在工件的一侧钻孔,只需一个位置和夹紧操作,这节省了时间,提高了生产率。

介绍

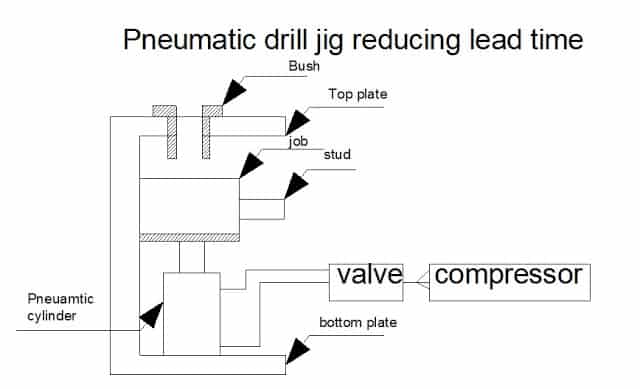

大规模生产的目标是通过降低安装成本和人工疲劳来提高生产率和精度。实现大规模生产目标的常见做法之一是使用夹具。让我们考虑一个例子,一个人得到一个1000个产品的订单,在一个工件上钻三个孔。在这种情况下,设计师会借助方形、直线度、划线器、中心冲头等来确定每个孔的位置。通常,试错法是实践,直到孔的轴线与钻的轴线正确对齐。因此,需要花费大量的时间来保持准确性。最终会增加操作员的疲劳。这样,操作员就不用借助方尺、直线度、划线器、中心冲头等来确定每个工件上每个孔的位置,而是使用夹具来定位和引导钻到合适的位置。钻模消除了个别标记、定位和频繁检查,提高了生产率。互换性是夹具的优点之一。 There is no need for selective assembly. Any of the parts will fit properly in the assembly and all similar components are interchangeable. In addition, a jig reduces the repetitive nature required for drilling a hole, as the locating, clamping and guiding are done by jig itself. The tool-guiding element helps in setting of tool in correct position. Hence, skilled workers are not required. Drill jig makes it possible to drill, ream and tap holes at much faster speed and with great accuracy as compared to holes produced by conventional hand methods. The responsibility for accuracy of hole location is taken from the operator and given to the jig. Jig can be defined as a work piece holding and locating device that positions and guides or controls the cutting tool. Drill jig is device to ensure a hole to be drilled, tapped or reamed in the work piece at proper place. Leaf jig consists of a clamping device to hold the part in the position under hardened steel bushings. Drill passes through the steel bushings during drilling operation. The drill is guided by these bushings. Generally work piece is held by jig and the jig is arranged in such a way that the work piece can be quickly loaded and unloaded.

优点:

•无需单独标记、定位和频繁检查。

•夹紧刚度高,提高了速度、进给和切削深度,缩短了操作时间。

•它在大规模生产中非常有用。

•可以雇佣非熟练或半熟练的操作员,节省劳动力成本。

•部分自动化工具。减少了机器零件质量控制的费用。

限制:

•仅用于小型部件。仅用于带法兰的弯头管,高度为mm。

•可能来自于处理。没有特殊的方法来去除钻孔产生的碎屑。所以它需要单独的时间。

应用程序

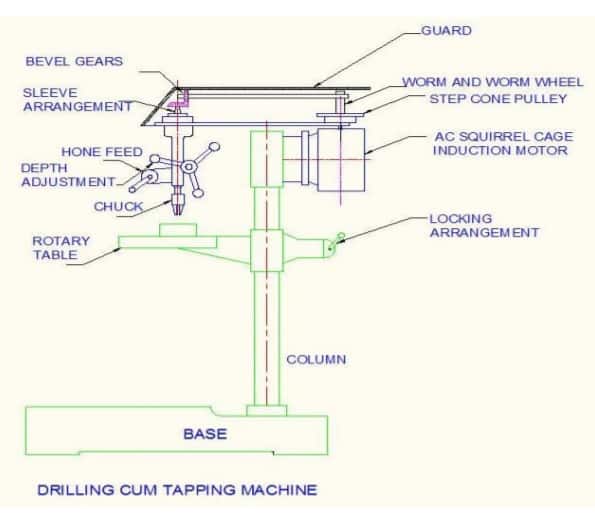

•批量生产:以下是使用夹具的部分生产操作列表:装配、研磨、镗床、铣床、拉削、计划、钻削、锯切、成形、成形、测量、冲压、磨削、攻丝、热处理、测试、珩磨、车削、检查、焊接

参见:指数

机械新项目,创新,想法

这是我的项目,我想要这个项目

我需要这个项目的完整报告。