Table of Contents

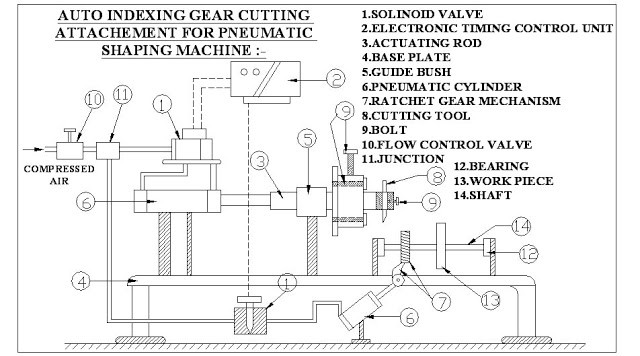

AUTO INDEXING GEAR CUTTING ATTACHMENT FOR PNEUMATIC SHAPING MACHINE

SYNOPSIS

介绍

这是自动化时代,广泛地定义为通过所有自动化程度的机械功率更换手动努力。虽然随着机械化程度的增加,该操作仍然是系统的重要组成部分,但随着机械化程度的增加,随着物理输入的要求。

Degrees of automation are of two types, viz.

- Full automation.

- Semi automation.

In semi automation a combination of manual effort and mechanical power is required whereas in full automation human participation is very negligible.

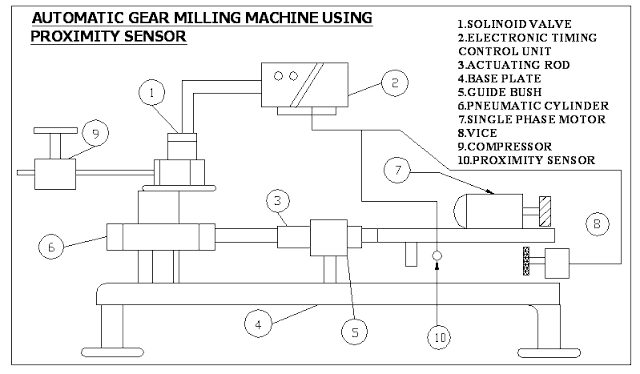

WORKING PRINCIPLE

- The compressed air from the compressor reaches the solenoid valve. The solenoid valve changes the direction of flow according to the signals from the timing device.

- 压缩空气通过5/2电磁阀,并且进入气缸体的前端。空气推动活塞为切割行程。

- 在切割冲程空气的末端,来自电磁阀到达缸体的后端。压力保持相同,但由于活塞杆的存在,该区域较少。这对活塞施加了更大的压力,以更快的速率推动它,从而实现更快的返回行程。

- The compressed air pass through the 3/2 solenoid valve and it is admitted into the front end of the cylinder block. The air pushes the piston for the gear changer. At the end of the cutting stroke air from the solenoid valve reaches the rear end of the cylinder block.

- 压力保持相同,但由于活塞杆的存在,该区域较少。这对活塞施加了更大的压力,以更快的速率推动它,从而实现更快的返回行程。

- The screw attached is fixed to the clapper box frame gives constant loads which lower the sapper to enable continuous cutting of the work.

- The stroke length of the piston can be changed by making suitable adjustment in the timer.

应用程序

- 中小型产业

- It is very useful in machine shop

- 工业应用

LIMITATIONS

- While working, the compressed air produces noise therefore a silencer may be used.

- High torque can not be obtained

- Load carrying capacity of this unit is not very high

ADVANTAGES

- Auto indexing mechanism is used to reduce the production time

- Quick response is achieved

- Simple in construction

- 与其他机器相比,单位的成本较少

- No fire hazard problem due to over loading

- Comparatively the operation cost is less

- The speed of forward and reverse stroke is varied

- Continuous operation is possible without stopping

More Resources /articles

iiiiiiii like thissssssssss

I am interested in AUTO INDEXING GEAR CUTTING ATTACHMENT FOR PNEUMATIC SHAPING MACHINE for my mtech project so I want to discuss price and what exactly this project is please give brief idea of exact model