Table of Contents

Introduction To Water Jet Machining Process | Advantages and Disadvantages

Introduction To Water Jet Machining :

Water Jet Machining(WJM) called hydrodynamic or equipment may be used for applications similar to the laser. Connection, except the obvious reasons.

Water Jet Machining Working Principle:

Water jet machinewidely used for cutting plastic, cloth, rubber, paper and leather, because of the lack of heat it produces kerf very narrow, and if set up correctly produce very smooth edges no scraps or burrsWater jet machineis a very clean job with no dust or noise, odor and very little, in fact, the health and safety and environmental impact is minimal, almost.

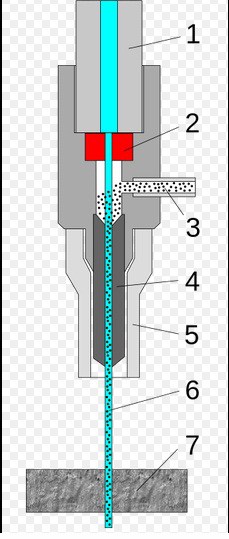

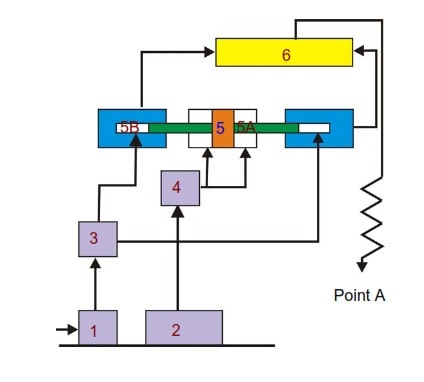

The waterjet cutting machine uses a stream of water and abrasive particles, such as garnet, to perform the cutting operation. The waterjet cutter takes city water (typically 80 psi), and through the use of an intensifier-type pump, pressurizes the water to 55,000 psi. When the abrasivejet cutting head is enabled, the water flows through a 0.010-inch diameter orifice into a mixing chamber. As the waterjet stream enters the mixing chamber, it creates a partial vacuum that draws the flow of abrasive particles through the abrasive delivery line. The abrasive particles combine with the waterjet stream to create the high energy abrasivejet cutting stream. This stream exits the cutting head at a velocity of up to 3,000 feet per second. Today’s waterjet cutting machines are CNC controlled for accuracy, repeatability and ease of setup

Parts Of Water Jet Machine:

- LP booster pump

- Orifice

- Hydraulic unit

- Mixing Chamber

- Additive Mixer

- Focussing tube or inserts

- Intensifier

- Accumulator

- Flexible high pressure

- transmission line

- On-off valve

- Catcher

- CNC table

- Abrasive metering device

- Catcher

General Water Jet Machining Process Parameters:

the general domain of parameters in entrained type AWJ machining system is given below:

• Orifice – Sapphires – 0.1 to 0.3 mm

• Focussing Tube – WC – 0.8 to 2.4 mm

• Pressure – 2500 to 4000 bar

• Abrasive – garnet and olivine – #125 to #60

• Abrasive flow – 0.1 to 1.0 Kg/min

• Stand off distance – 1 to 2 mm

• Machine Impact Angle – 60 to 90

• Traverse Speed – 100 mm/min to 5 m/min

• Depth of Cut – 1 mm to 250 mm

Advantages of Water Jet Machining (WJM):

- Water jet machining is a relatively fast process.

- It prevents the formation of heat affected zones on the workpiece.

- It automatically cleans the surface of the workpiece.

- WJM has excellent precision. Tolerances of the order of ±0.005″ can be obtained.

- It does not produce any hazardous gas.

- It is eco-friendly.

Disadvantages of Water Jet Machining:

- Only soft materials can be machined.

- Very thick materials cannot be easily machined.

- Initial investment is high.

Application Of Water Jet Machining:

The applications and materials, which are generally machined using WJ and AWJ, are given below:

• Paint removal

• Cleaning

• Cutting soft materials

• Cutting frozen meat

• Textile, Leather industry

• Mass Immunization

• Surgery

• Peening

• Cutting

• Pocket Milling

• Drilling

• Turning

• Nuclear Plant Dismantling

Download:

More Resources /articles