Table of Contents

Mini Diploma Project | FLUID HYDRAULICS OPERATED ROBOTIC ARM

INTRODUCTION ABOUT THE MECHANISM

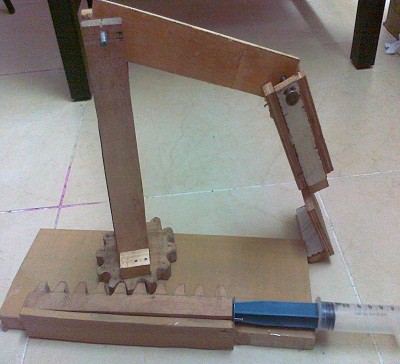

A robotic arm which is hydraulically operated and controlled by syringes filled with some fluid. It consists of various parts connected to each other in a pre-designed manner which are guided in a constrained way to obtain required output.

APPLICATION

These arms are used in assembly lines of mega factories to assemble various parts of a product and also to paint vehicles. They are also used in earth movers to pick up heavy weight and keep them where required. Same principle is being used in JCB’s, automobile lifters, etc.

PARTS

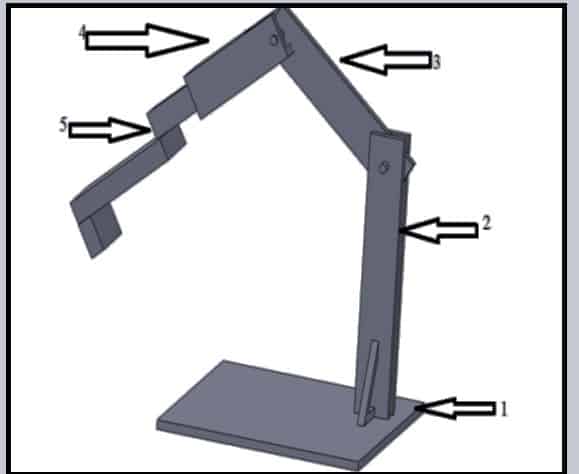

- In the mechanism, each part has been provided with certain degree of freedom to move in a constrained way to guide other parts and also to pick up small weight items and to place them wherever required.

- The complete mechanism consists of a fixed vertical link.

- To its free end is connected or better to say hinged, another horizontal link which is free to oscillate about that hinge in an up-down way of motion.

- To this link is connected a slotted type mechanism which consists of a slotted box which itself can oscillate about its hinge and in it is a sliding link which can come out of the slot to have the slider like motion.

- 这个滑块连接表面,下面which are attached 4 spoons acting as arm to pick up the items.

- The entire mechanism is fixed on a rack and pinion type mechanism to allow degree of freedom of the mechanism as a whole to rotate by 130degrees.

CONCEPT

The basic concept used behind the operation is PASCAL’s LAW. This law states that when a pressure is applied at one point of a fluid contained in a constrained volume, then the pressure due to that force is equally transmitted to all the points of the fluid, which are acted upon by the same pressure.

Using the same principle, we applied pressure to fluid in syringe which is transmitted to other end of tube which is connected to a syringe. This motion of the syringe is used to move the links or parts of the mechanism which are attached to respective syringes.

CONCEPTUAL DESIGN

1.) The slotted mechanism used in the design, increases its complexity but at the same time increases its efficiency, ability, area of coverage.

2.) Rack and pinion mechanism used to provide rotatory motion does its work smoothly without any jerks or shocks and giving more degree of rotation and thereby increasing the area of effect.

3.) To increase overall stability and to avoid roll over or unbalancing due to torque or extra weight in the front part, suitable counter weight is used in the rear portion of the mechanism.

4.) Soap water having least compressibility and high efficiency is used as a fluid in syringes.

DEVELOPMENT OF MODEL

The complete development of the parts was brought out in the machine shop. Wood was selected as raw material for the weight factor and also due to its ease of being machined.

Using different power tools and putting our own effort, all the parts of the mechanism were prepared according to the dimensions pre-decided.

First the entire set-up or mechanism was prepared in SOLID WORKS software and similar calculations were done to bring out the prototype and make it work effectively and efficiently.

CONCLUSION

The prepared mechanism has been successfully constrained and executed to carry out the required work of picking up the weight of objects like table tennis balls and to put them into glasses placed at different location.

More Resources /articles

I recently came across your blog and have been reading along. I thought I would leave my first comment. I don't know what to say except that I have enjoyed reading. Nice blog. I will keep visiting this blog very often.Donald